One of the most important preventative maintenance procedures performed by technicians on conveyor systems is belt tracking. Indeed, mistracking can be a costly issue for businesses if maintenance is not performed regularly, which is why technicians routinely perform belt tracking to ensure everything is in order.

In today’s blog, we share how conveyor belt tracking is done during maintenance sessions.

First, technicians will have to perform a pre-tracking inspection. This inspection ensures that all the elements are in their proper place. If even one component has not been adjusted properly, conveyor belt tracking will be unsuccessful.

Here is what the inspection procedure looks like:

- Technicians have to first ensure the conveyor is level, both width and length-wise. You may adjust the conveyor’s supports if not.

- Conveyor belts are tracked by adjusting the drive pulleys, return idlers, tail pulleys, and snub idlers. As such, technicians will need to inspect these components to ensure they are square with the conveyor bed.

- The conveyor belt has to be checked to ensure that it has been threaded properly through the conveyor.

- The conveyor belt’s lacing has to be inspected for proper installation and that it is square with the belt.

- Loading has to be done correctly. The feed should be in the direction of belt travel and items should be centred on the belt.

- The conveyor needs some time to adapt to any adjustments that may have been made. Technicians should allow the conveyor to perform several revolutions before observing the conveyor from the tail pulley looking toward the drive, checking for consistency.

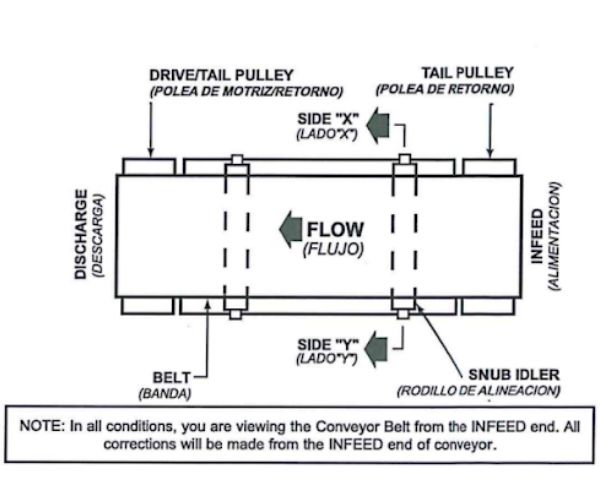

After the pre-tracking inspection is complete, the belt will need to be steered into the correct position. Belt steering is relatively easy. Refer to the image below:

Assuming the belt is running in the same direction as the arrow in the figure above but tracking towards side “X”, you will have to move the snub idler nearest to the infeed end of side “Y” towards the discharge end of the conveyor to steer the belt.

In the same scenario, if the belt is tracking towards side “Y”, move the snub idler nearest to the infeed end of side “X” towards the discharge end of the conveyor.

If the belt flow is reversed, note that you will have to view the conveyor from the opposite end while performing the steering. Aside from this, all the same conditions apply.

These basic steps are the foundation of any conveyor belt tracking operation during maintenance sessions. With decades of experience in the material handling industry, we at Norpak Handling have seen the negative effects of businesses neglecting routine maintenance. In order to ensure the best performance from your conveyors, make sure you undertake maintenance operations frequently.