Drive

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. We offer several controls options including:

- Stand alone control panel with interface capabilities

- Prewired motor disconnect

- Proximity sensors prewired to a central junction box

- Prewired missing slat detection sensors.

Save on production costs as well as space with the Mass Flow spiral conveyor. Ideal for empty or full bottles, jars, cans and other small containers, this spiral conveyor will reliably convey up to 2,000 units per minute. With the added benefit of being low maintenance, this spiral is a great addition to any production line.

Mass Flow Spiral Features:

Modular Design

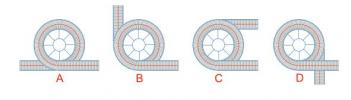

- An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. Custom configurations are available. All configurations can operate up or down in a clockwise or counterclockwise rotation.

Controls and Integration

- Most of our spirals are shipped without controls because they normally integrate with an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and one for the overload protection device. A Variable Frequency Drive (VFD) is required for proper operation of the spirals.